100% recycled cobalt will be used in all Apple-designed batteries, in addition to the rare earth elements in their magnets, tin solder and gold plating on circuit boards to further improve sustainability by 2024, the company announced today.

Since 2022, Apple has expanded its use of non-virgin material, with over 95% of tungsten in their products now being 100% recycled, according to the company.

The Cupertino tech giant is working towards their products being carbon neutral by 2023, according to Lisa Jackson, Apple’s VP of Environment, Policy and Social Initiatives. In 2022, 25% of Apple’s cobalt came from recycled sources, almost double the amount in 2021. Cobalt mining comes at a cost to the environment and the health of the local population where the mines are, so recycling the element is vital to limit harm.

Discover new horizons, always connected with eSIM

Travel the world stress and hassle-free with the best eSIM service available. Enjoy unlimited data, 5G speeds, and global coverage for affordable prices with Holafly. And, enjoy an exclusive 5% discount.

The iPhone 14 lineup is designed with 100% recycled rare earth elements in all magnets, 100% recycled tungsten in the Taptic Engine, 100% recycled tin in the solder of multiple PCBs and 100% recycled gold in the plating of the circuit boards too.

Apple has also eliminated plastics from most of its packaging, replacing display films, wraps and foam cushioning, and is even looking at changing fibre alternatives to stickers and lamination to minimise the remaining 4% plastic in their packaging footprint.

Our ambition to one day use 100 percent recycled and renewable materials in our products works hand in hand with Apple 2030: our goal to achieve carbon neutral products by 2030

Lisa Jackson – Apple VP of Environment, Policy, and Social Initiatives

Reclaiming the materials at the end of a product’s life is another area Apple continues to innovate, partnering with the Material Recovery Lab in Austin, TX where Apple’s engineers work alongside lab experts to refine new product design choices that make future recycling more achievable.

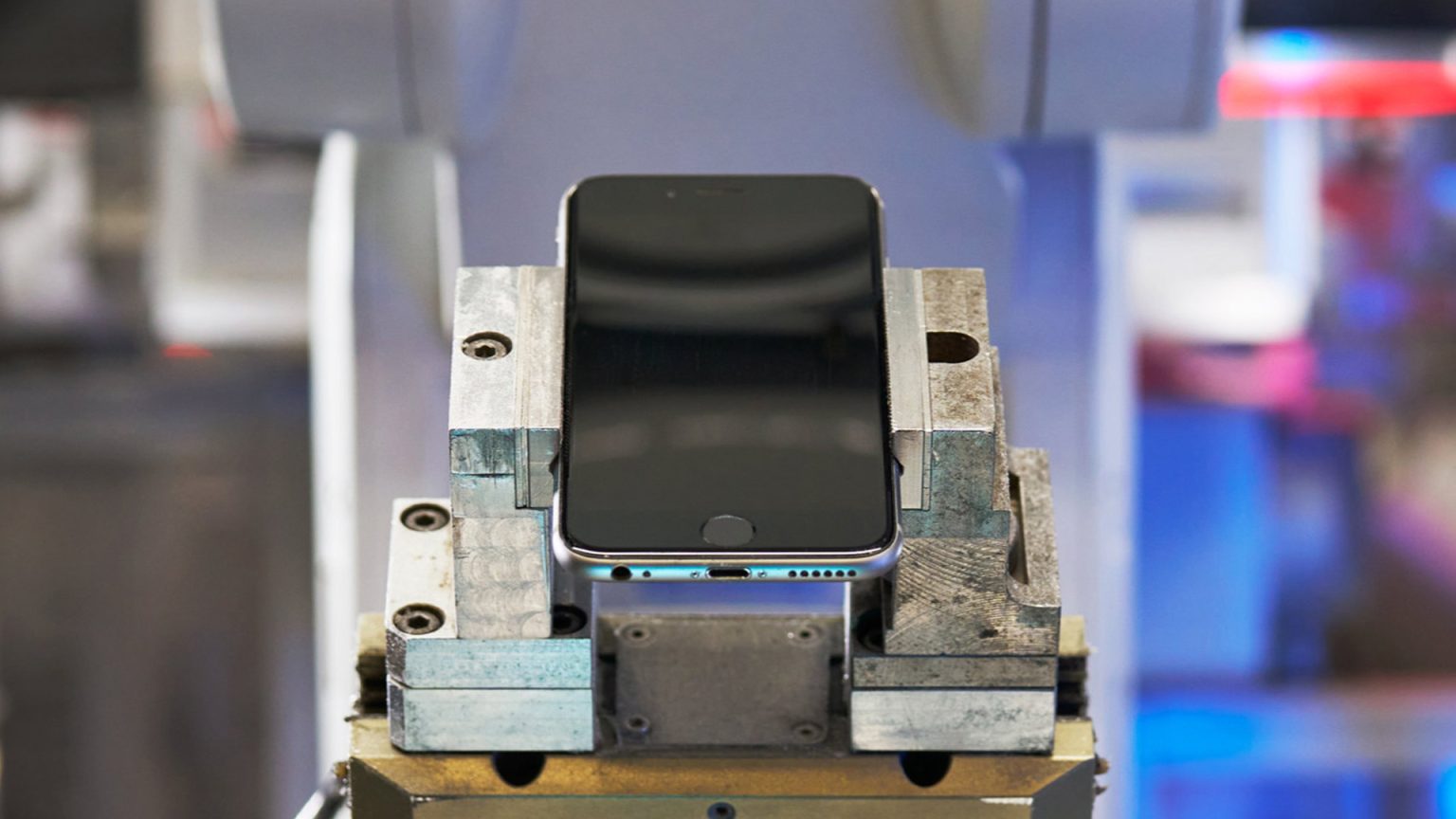

In addition to the well-publicised Daisy iPhone dismantling robot, their robot “Dave” has been deployed with a recycling partner in China and assists in the recovery of rare earth elements by dismantling Taptic Engines.

Apple is also implementing AR overhead projection systems that can guide recycling partners on disassembling MacBooks and iPads by projecting video imagery directly onto the products as they are dismantled. This offers step-by-step instructions and safety information to ensure safety throughout the process. Apple says these innovations will bring them closer to its “ambitious goal to be carbon neutral across its entire supply chain and the life cycle of every product by 2030.”